Starting from:

$8

Home

Linde

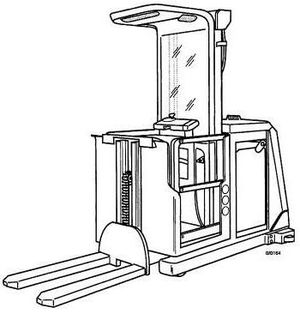

Linde E14, E16(,C,P), E18(C,P), E20P Expl.Prot. ForkLift Truck 335-02 Series Service Training Manual

Linde E14, E16(,C,P), E18(C,P), E20P Expl.Prot. ForkLift Truck 335-02 Series Service Training Manual

Original Illustrated Service Training Manual for Linde Explosion Proof Electric Lift Truck 335-02 Series with gas warning system PL-G 1000 to EN1755 models E14, E16, E16C, E18C, E16P, E18P, E20P

Covered models:

E14-02

E16-02

E16C-02

E18C-02

E16P-02

E18P-02

E20P-02

Format: PDF, 94 pages

Language: English

Contents:

General information

Instructions

Explosion-proofing of the truck

Traction motors

Pump motor

Safety rules

Battery

Backup battery

Commissioning

Battery installation and replacement

Operation and charging

Maintenance

Wheels

Service brake

Fork arms

Electrical equipment

Indicators and signal lamps

Bolt tightening torques for housing covers on flameproof enclosures

Special tools

1 Drive system - Traction motors

1.1 Traction motor

1.1.1 Technical specifications

1.1.2 General remarks

1.1.3 Checking traction motor carbon brush wear and replacing the carbon brushes

1.1.4 Cleaning the traction motors

2 Drive system - Gearing

2.1 Dismantling and re-installing the drive axle

2.1.1 Dismantling the drive axle and cleaning the traction motors

4 Wheels and tyres

4.1 Checking the leakage resistance of the drive tyres

6 Electrical equipment

6.1 Sealed housings

6.1.1 Maintenance of sealed housings

6.1.2 Control housing

6.1.3 Lighting control housing

6.1.4 Housing for gas warning system

6.1.5 Checking the sealing effect of the PG cable glands

6.1.6 Checking the condition and firm attachment of electrical cables

6.2 Gas warning system

6.2.1 Description

6.2.2 Installation and removal of the acknowledgement and channel modules

6.2.3 Taking the gas warning system into service

6.2.5 Setting the alarm thresholds of the channel modules

6.2.4 Setting the sensor current

6.2.6 Setting the alarm thresholds

6.2.7 Calibrating the sensor head with test gas

6.2.8 Malfunctions

6.2.9 Troubleshooting

6.3 LDC power supply

6.4 Timing circuit 1 V1 and release signal - LDC

6.5 Circuit diagram LDC

6.5.1 Traction controller LDC

6.5.2 Voltage transformer, temperature monitoring, composite instrument - LDC

6.5.3 Lifting electronics LDC

6.5.4 Traction electronics LDC

6.5.5 Gas warning system PL-G1000

6.5.6 Lighting system and additional electrical equipment - LDC

6.5.7 Extra equipment flash light and reverse warning light LDC

6.6 Power supply LDC40

6.7 Timing circuit 1 V1 and release signal LDC40

6.8 Circuit diagram LDC40

6.8.1 Traction controller LDC40

6.8.2 Composite instrument and temperature control, LDC40

6.8.3 Composite instrument and options LDC40

6.8.4 Combination controller LDC40

6.8.5 Gas warning system PL-G1000 LDC40

6.8.6 Lighting system and additional electrical equipment LDC40

6.8.7 Additional equipment - Flash light and reversing warning

7 Working hydraulics

7.1 General remarks

7.2 Renewing the carbon brushes on the pump motor

Covered models:

E14-02

E16-02

E16C-02

E18C-02

E16P-02

E18P-02

E20P-02

Format: PDF, 94 pages

Language: English

Contents:

General information

Instructions

Explosion-proofing of the truck

Traction motors

Pump motor

Safety rules

Battery

Backup battery

Commissioning

Battery installation and replacement

Operation and charging

Maintenance

Wheels

Service brake

Fork arms

Electrical equipment

Indicators and signal lamps

Bolt tightening torques for housing covers on flameproof enclosures

Special tools

1 Drive system - Traction motors

1.1 Traction motor

1.1.1 Technical specifications

1.1.2 General remarks

1.1.3 Checking traction motor carbon brush wear and replacing the carbon brushes

1.1.4 Cleaning the traction motors

2 Drive system - Gearing

2.1 Dismantling and re-installing the drive axle

2.1.1 Dismantling the drive axle and cleaning the traction motors

4 Wheels and tyres

4.1 Checking the leakage resistance of the drive tyres

6 Electrical equipment

6.1 Sealed housings

6.1.1 Maintenance of sealed housings

6.1.2 Control housing

6.1.3 Lighting control housing

6.1.4 Housing for gas warning system

6.1.5 Checking the sealing effect of the PG cable glands

6.1.6 Checking the condition and firm attachment of electrical cables

6.2 Gas warning system

6.2.1 Description

6.2.2 Installation and removal of the acknowledgement and channel modules

6.2.3 Taking the gas warning system into service

6.2.5 Setting the alarm thresholds of the channel modules

6.2.4 Setting the sensor current

6.2.6 Setting the alarm thresholds

6.2.7 Calibrating the sensor head with test gas

6.2.8 Malfunctions

6.2.9 Troubleshooting

6.3 LDC power supply

6.4 Timing circuit 1 V1 and release signal - LDC

6.5 Circuit diagram LDC

6.5.1 Traction controller LDC

6.5.2 Voltage transformer, temperature monitoring, composite instrument - LDC

6.5.3 Lifting electronics LDC

6.5.4 Traction electronics LDC

6.5.5 Gas warning system PL-G1000

6.5.6 Lighting system and additional electrical equipment - LDC

6.5.7 Extra equipment flash light and reverse warning light LDC

6.6 Power supply LDC40

6.7 Timing circuit 1 V1 and release signal LDC40

6.8 Circuit diagram LDC40

6.8.1 Traction controller LDC40

6.8.2 Composite instrument and temperature control, LDC40

6.8.3 Composite instrument and options LDC40

6.8.4 Combination controller LDC40

6.8.5 Gas warning system PL-G1000 LDC40

6.8.6 Lighting system and additional electrical equipment LDC40

6.8.7 Additional equipment - Flash light and reversing warning

7 Working hydraulics

7.1 General remarks

7.2 Renewing the carbon brushes on the pump motor

1 file (30.2MB)